Shape memory alloys (SMA), as NiTi,

exhibit very peculiar and interesting functional properties due to the

occurrence of a solid-to-solid phase transition involving the so-called

austenite

and martensite phases, favored at high and low temperature, respectively.

The phase transition involves a change in the macroscopic shape of a device

made of SMA, so that SMA plays simultaneously the role of temperature sensor

and actuator. Distinctive features of the actuation are, for instance,

the strong force that can be delivered and the sudden recovery of the original

shape once the critical temperature of the transition is attained.

In the past, those features have been

widely exploited in devices based on bulk SMA. More recently, miniaturization

issues and biocompatibility of most SMAs, including NiTi, have stimulated

efforts for the production of shape memory films. Data in the following

table, where different actuation principles are compared, demonstrate the

performances which SMA can attain in micro electro-mechanical systems

(MEMS):

| Principle | Energy density

(J/cm3) |

Drive conditions | Scalability | Power/weight |

| Magnet Motor | 1 | B~1 T | Poor | Low |

| Electrostatic | 0.5 | 300 kV/mm | Good | High |

| Piezoelectric | 10-3 | 30 kV/mm | Good | High |

| SMA | 5-10 | 1 W/mm3 | Good | High |

Even if PLAD is used mostly in the fabrication of ceramic films, thanks to its flexibility it can easily be adapted to SMAs. Main problems encountered in NiTi film production are the formation of non-stoichiometric precipitates, known to inhibit shape memory phase transition, and the control of the stoichiometry (i.e., the relative content of Ni and Ti elements), which affects dramatically the critical temperatures of the phase transition. Advantages offered by PLAD with respect to more traditional deposition methods are:

At present, we are working with high purity Ni49Ti51 targets (produced at TEMPE/CNR Sez. Lecco) with critical temperatures well above zero. So far, we have deposited (anchored) films on Si/SiO2 substrates which have been tested by investigating the electrical properties as a function of the film temperature (R vs T measurements). In fact, the occurrence of the phase transition affects most of the physical properties of the sample, including its resistivity. As an example, the following plot shows a remarkable hysteresis in the R vs T curve, ascribed to the austenite-martensite transition, with critical temperatures in good agreement with those of the target material.

In the future, we plan to investigate PLAD of NiTi films on flexible polymer substrates (Kapton-like), that would represent a very important step forward to applications. This task will require a careful search for suitable deposition parameters, to be investigated with the help of our facilities for in-situ process diagnostics. In addition, we will start exploring the feasibility of prototypal devices employing PLAD NiTi films (for a review on possible applications of SMA in MEMS, visit the web pages of MiTech Lab at Scuola Superiore Sant'Anna, Pisa).

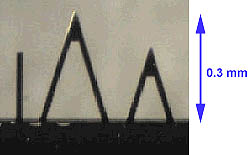

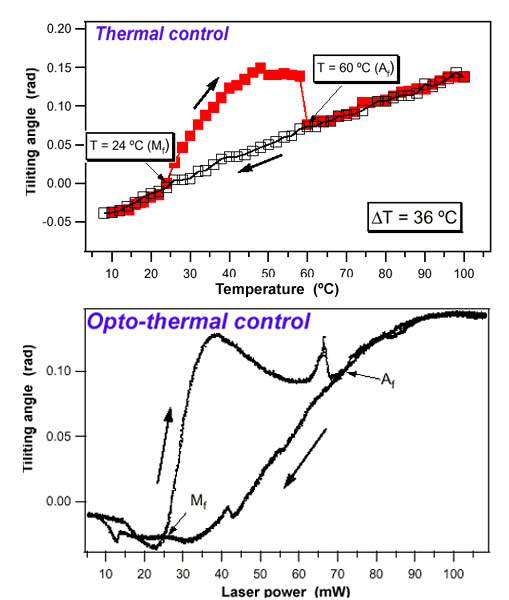

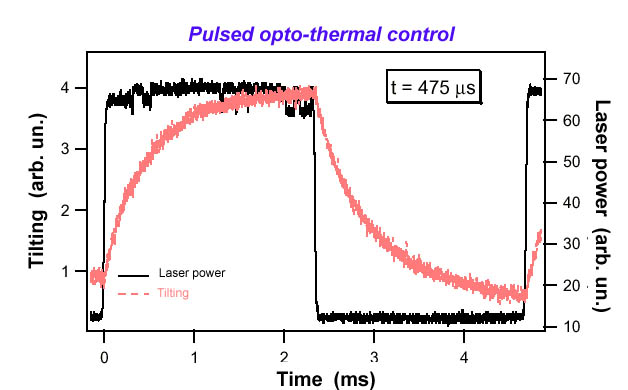

Investigation of the NiTi coated cantilevers has been carried out by exploiting an optical-lever system able to precisely measure the cantilever tilting. The sample has been placed in contact with a Peltier-driven thermal bath, and a near-IR laser has been used to optically actuate the cantilever. Thanks to the use of a Ni:Ti 49:51 target (obtained by TEMPE/CNR, Sez. Lecco), operation in air is possible, starting from room temperature. Results demonstrate the potential of the system, achieved in a simple and ruggedized system (thousand of thermal cycles have been applied without noticing any decrease in the mechanical performances). The findings suggest the occurrence of bi-metal mechanical actuation along with remarkable shape-memory effect, which will be exploited to deveop innovative MEMS devices with superior performance in terms of exerted strenght and response time.

You can see a slide-based contribution (presented at e-MRS Spring Meeting 2002, Symposium D) by clicking here.

You can see a slide-based contribution (presented at e-MRS Spring Meeting 2002, Symposium D) by clicking here.

Tilting angle of a 0.3 mm cantilever under thermal and opto-thermal control. The presence of an hysteresis loop demonstrates the occurrence of shpae-memory transformation, with typical temperature compatible with the nominal composition of the film.

Tilting of the cantilever under pulsed opto-thermal control. The cantilever switching time is below 0.5 ms, opening the way for applications in all-optical switching systems.